Personalized textile printing - from T-shirts to bed linen

We print your image, photo, logo or slogan on a T-shirt. As a gift, corporate logo T-shirt, for bachelor/bachelorette parties, graduation parties or similar.

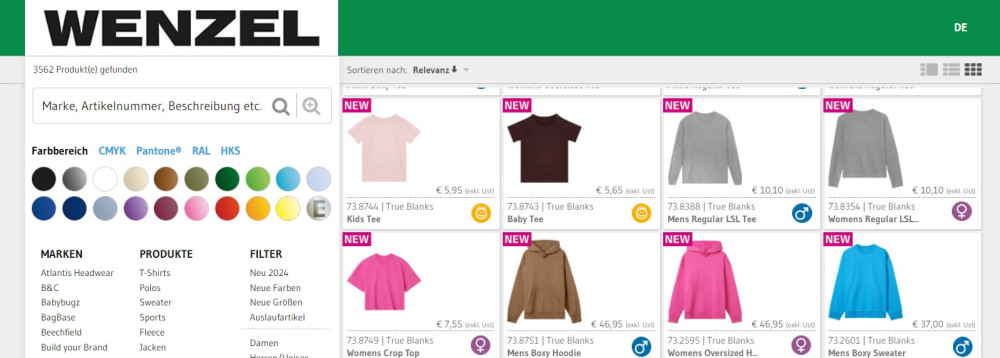

Textile catalog - Search for your desired textiles in our online catalog

A very large selection of textiles in all styles and cuts from:

T-shirts, polo shirts, longsleeves, pants, sweatshirts, hoodies, pullovers, tank tops, caps, underwear and much more awaits you.

You are welcome to our discounted online catalog browse for your desired textiles: Link: WENZEL-Textilworld

If you have found a suitable textile, please send it to us:

- Item numbers

- Sizes

- Colors

- Quantity

Areas of application

Textile printing for all

Would you like to realize your creative idea for a stag party or are you looking for a gift for newborns or schoolchildren? we print your T-shirts, sweat jackets, cloth bags, baby rompers and much more with your desired motif or slogan.

With matching hoodies, jerseys, tracksuits, fan shirts, cloth bags, cloth bags and much more, your appearance will be unique and give you a special sense of belonging. We make sure that you stand out from the crowd and clearly express your identity.

Which printing processes are best suited?

DTF transfer printing

DTF stands for "Direct to Film" and refers to a special type of transfer printing. DTF transfer printing is a digital printing process in which the design is printed directly onto a special transfer film. The design is then transferred from the film to the textile.

The DTF transfer printing process looks something like this:- The desired design is created on the computer and prepared for printing.

- The design is printed onto a special transfer film using special DTF printers. A special ink is used to ensure good adhesion to the film.

- After the design has been printed on the transfer film, the print is cured. This is usually done using heat and UV light to dry and fix the ink.

- The printed transfer film is placed on the textile and fixed with heat and pressure. The combination of heat and pressure enables the ink to transfer from the transfer film to the textile and adhere there permanently.

DTF transfer printing offers various advantages. It enables the printing of high-resolution designs with fine details and color gradients. There are no restrictions on the number of colors or the complexity of the design. DTF transfer printing can also be used on a wide range of textiles, including cotton, polyester, blended fabrics and other materials.

The surface of DTF transfer printing can vary depending on the print quality and materials used. As a rule, the result is a smooth and flexible surface that is pleasant to the touch. The print may have a slight relief, especially for designs with a white underlay to intensify the colors.

DTF transfer printing is a relatively new technology and is becoming increasingly popular due to its versatility and ability to produce high quality, detailed prints on a variety of textiles.

Sublimation printing

Sublimation printing is a printing process in which dyes change into a gaseous state without first becoming liquid.- The desired design is printed on a special transfer paper with sublimation-capable ink.

- The printed transfer paper is placed closely together with the material to be printed, usually polyester or a polymer-coated material.

- The combination of heat and pressure is exerted on the transfer paper and the material. This causes the dyes on the transfer paper to change into a gaseous state.

- As the material has an open porous structure, the gaseous dyes can penetrate the fibers. As soon as the heat is removed, the dyes condense back into the solid state and are now permanently in the fibers.

- enclosed in the fibers of the material.

The end product has a high level of color brilliance and durability, as the color is embedded in the material and not on the surface. Sublimation printing is often used for textiles such as sportswear, T-shirts, flags, banners, but also for other products such as mugs, cell phone cases and mouse pads. Sublimation printing only works on materials that have a special coating for the dye absorption process. The process is therefore mainly suitable for polyester and certain polymer-coated materials.

Sublimation printing does not lead to a noticeable increase in the surface area of the material, as the dyes penetrate directly into the material. This means that the end product retains a smooth texture, which is particularly beneficial for textiles as there are no distracting layers on the surface. Sublimation printing enables a high resolution and therefore a detailed and photorealistic representation of the design. This is particularly important when fine details or complex patterns are to be printed. Overall, sublimation printing offers a high-quality, durable and photorealistic look that is particularly suitable for certain applications such as sportswear, promotional items and personalized gifts.

Contact our customer service!

info@wenzel-muc.de

info@wenzel-muc.de +49 89 26 66 62

+49 89 26 66 62 Branches

Branches Contact form

Contact form