Perfect binding with only a few pages

WENZEL now offers perfect binding (softcover and hardcover) with just a few pages. The "Morgana", which has found its way into our machine park, requires a spine width of just 1 mm.

Dear readers,

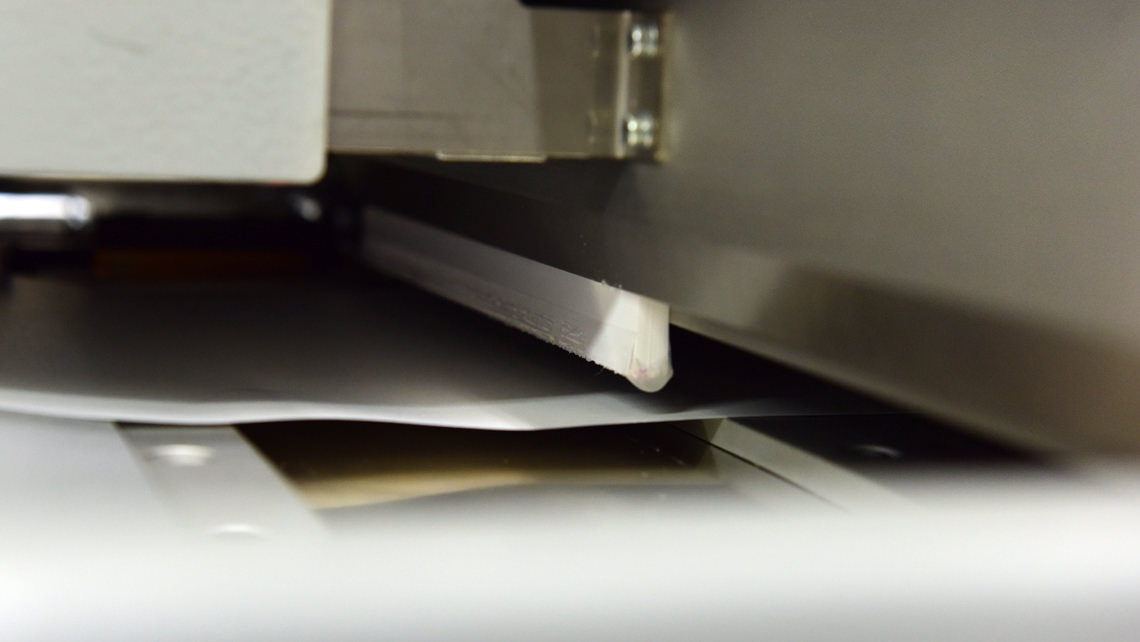

Softcover bindings can now be realized at WENZEL with considerably fewer sheets than before (see photos to browse through!). Normally we need a spine width of 4 - 5 mm and thus approx. 40 - 50 sheets to create a hardcover binding. If there are too few pages, the binding will fall apart when the book is opened as the glue will not hold. Fortunately, this limitation has now come to an end.

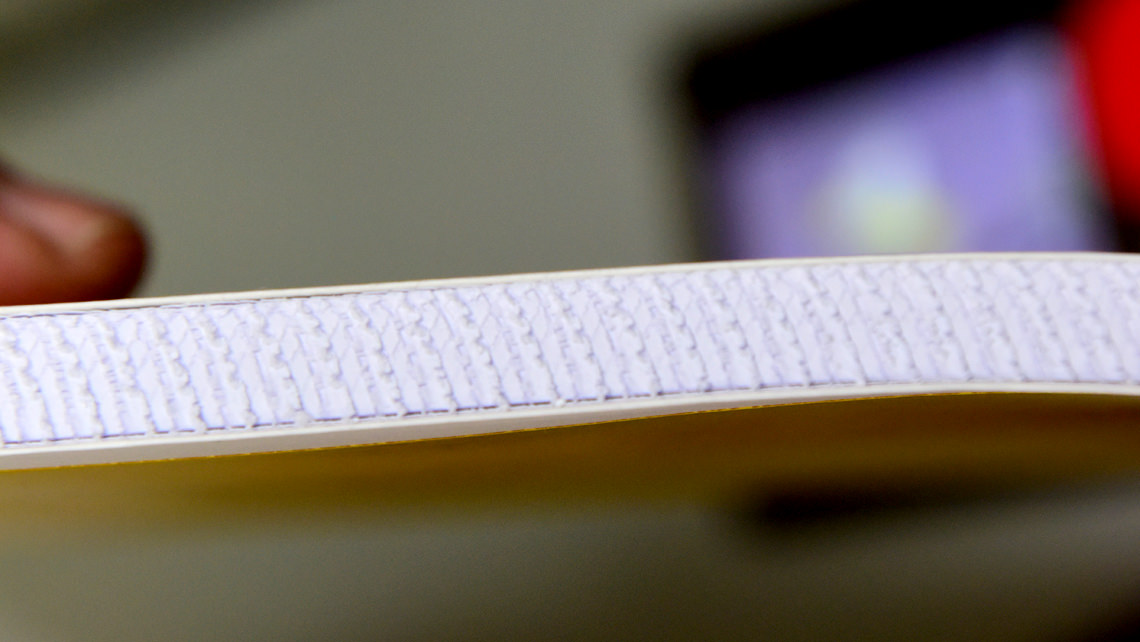

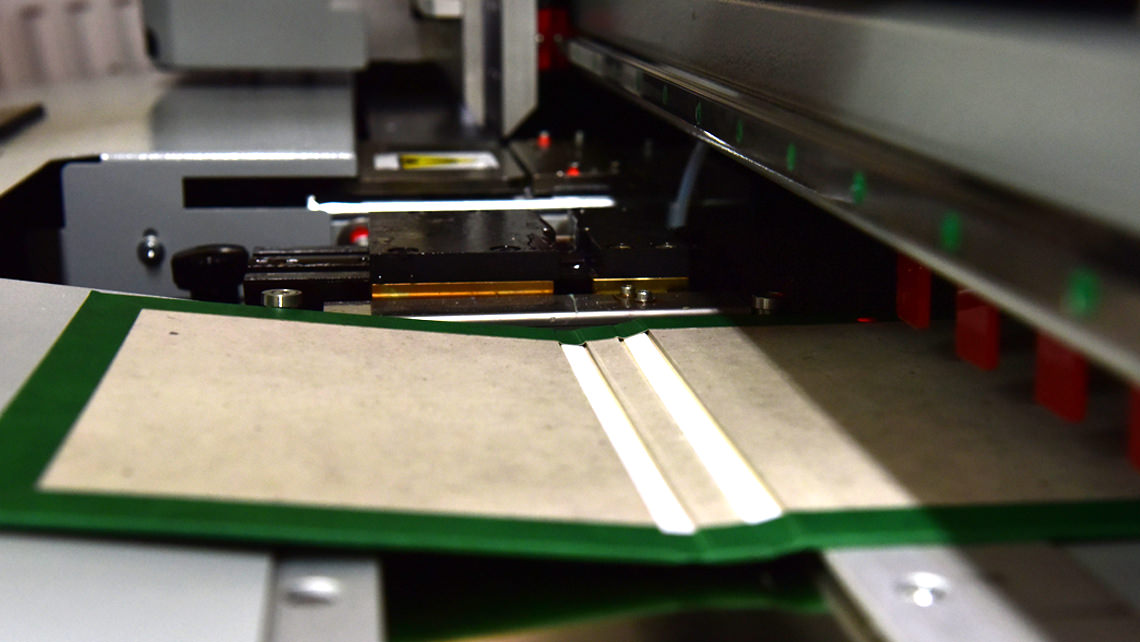

Softcover binding with only 1mm spine width

With our new machine, the "Morgana Digibook 200", we are able to produce softcover bindings with a very narrow spine. Only 1mm is the minimum, which corresponds to about 10 sheets of 100g/sqm. This means that the inner part can now also correspond to a short work and we can still produce it and offer it as a softcover binding. The maximum width, on the other hand, is 50mm, which corresponds to approx. 500 sheets.

Fast processing, circulation does not matter

Fortunately, we can produce up to 200 books per hour with this machine. This means that even small print runs do not become more expensive, but WENZEL can maintain an attractive price. Larger print runs, on the other hand, can be bound extremely quickly with good planning. However, this does not include the drying phase, which takes 24 hours. The books should not be opened any sooner.

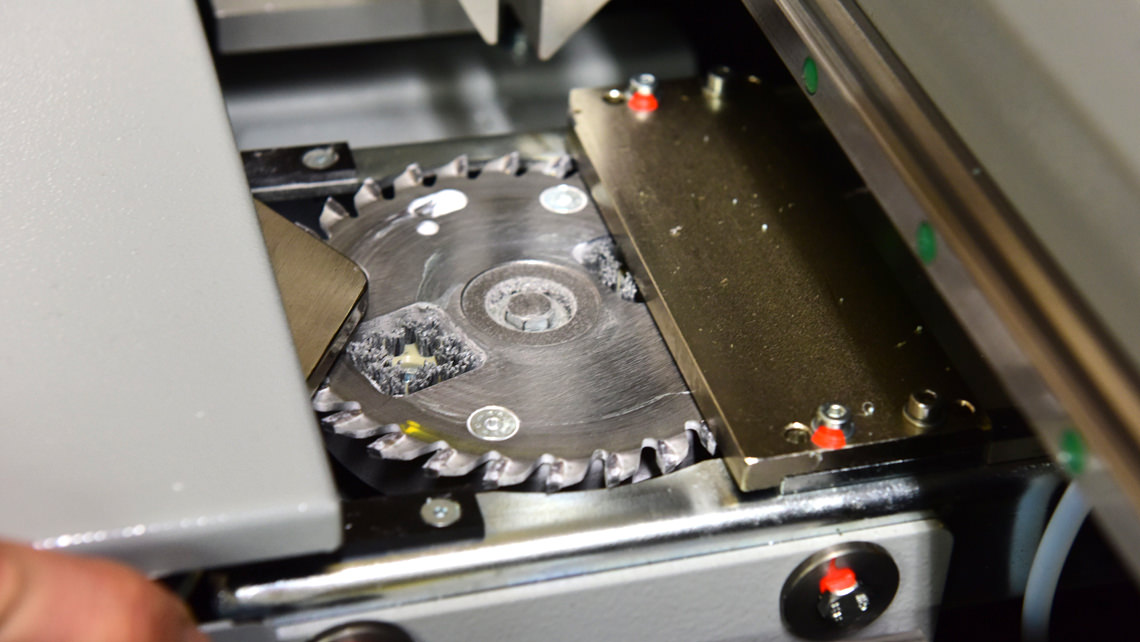

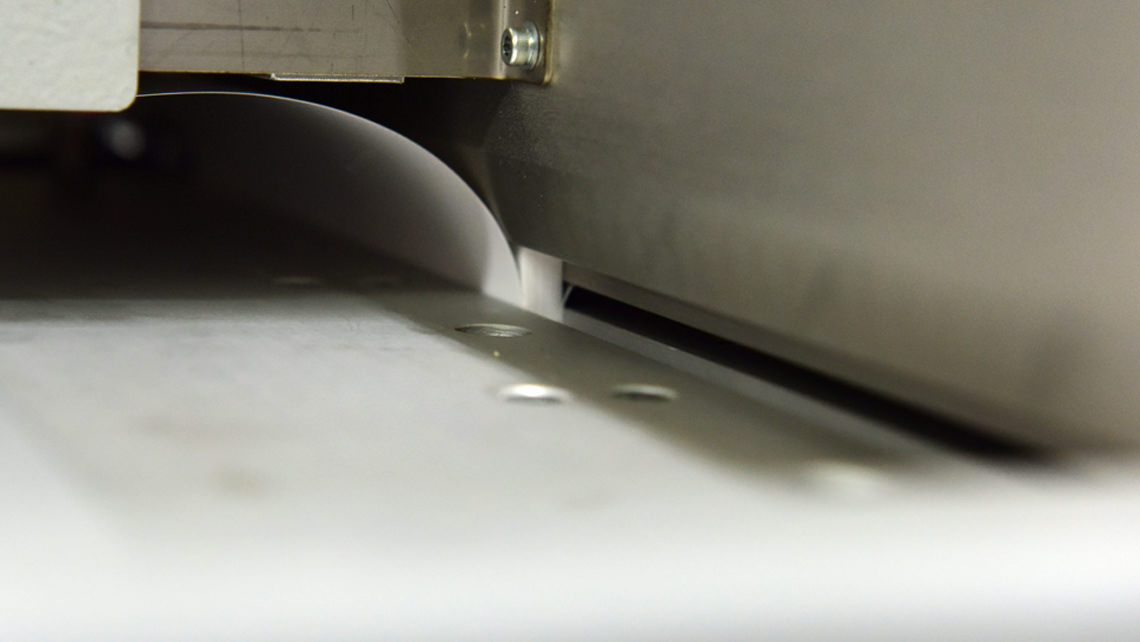

Roughening the blades with a saw blade

Before we start gluing, we roughen the printed matter with a kind of saw. The stack of paper passes through a saw blade and is rubbed and slightly spread on the back. This allows the glue to adhere better and spread evenly, which increases the adhesive effect and therefore the durability.

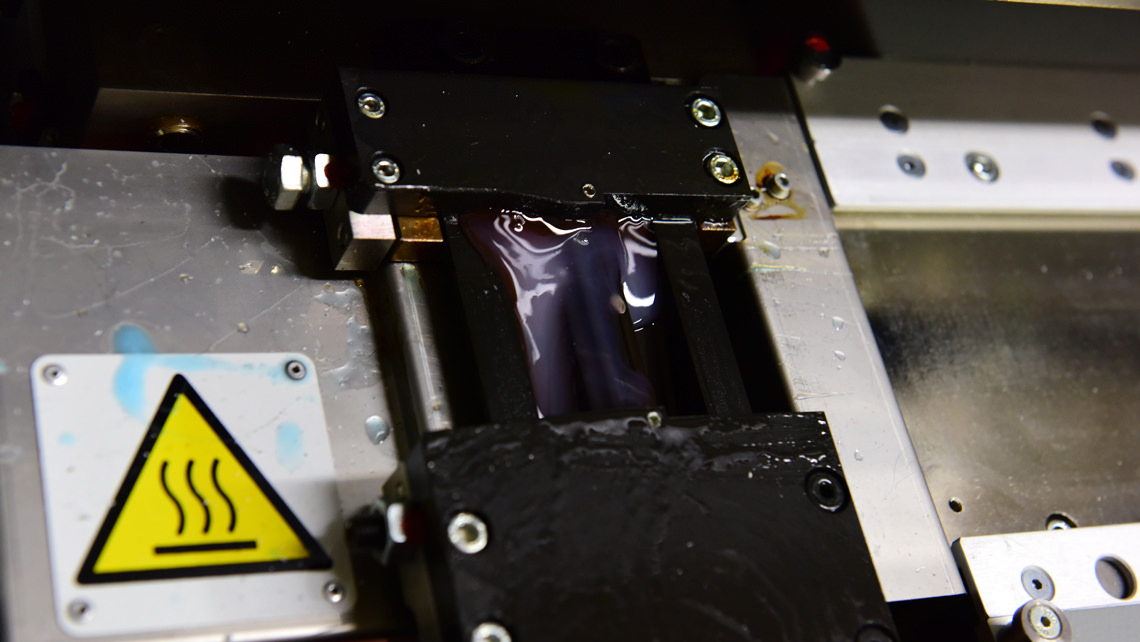

New PUR adhesive makes it possible

The hardcover and softcover bindings with just a few pages are made possible by a new type of adhesive, the PUR adhesive (polyurethane). As soon as it is applied and comes into contact with air, it hardens immediately. This means that bindings must be processed immediately after the glue has been applied, which happens straight away with the Morgana. This also means that the glue must never come into contact with air beforehand, as it reacts immediately. Everything happens in secret, so to speak.

If you also have an adhesive binding to do, please get in touch with us. It (almost) no longer matters how many pages it contains.

Your

Matthias Wenzel